You are in:

Fuel

System |

General

Maintenance - Fuel System

| The fuel system consists of a petrol

tank, a mechanical fuel pump operated from the

engine camshaft, and a carburettor of the

downdraught type with the necessary fuel

connecting lines. A fuel tank is located

either:

- at the rear

of the car beneath the luggage

compartment (Saloon and Estate)

- at the rear

of the vehicle on the left hand side

(Van)

The

quantity of fuel in the tank is registered on the

fuel gauge when the ignition is switch

“on”. The gauge is designed to

eliminate needle fluctuation whilst the ignition

is switch on.

The

fuel tank filler is located :

- to the right

of the rear number plate (Saloon and

Estate)

- to the rear

of the van on the on the left hand side

(Van)

The

filler cap may be easily removed by turning it in

an anti clockwise direction. Make sure that the

filler cap is replaced securely and see that the

vent hole is clear of obstructions at all times,

otherwise failure of the fuel supply to the

carburettor may result.

The engine is

designed to operate on premium grade fuel. An

optional low compression cylinder head is

available should it be necessary to use low grade

fuel.

|

Fuel

Pump

This is mounted on the right hand side of the

cylinder block, is entirely automatic in action.

It requires little attention other than cleaning

the filter screen regularly and removal of

sediment from the pump chamber. The fuel pump can

be one of two types. One type had a domed metal

cover and the other an inverted glass sediment

bowl. |

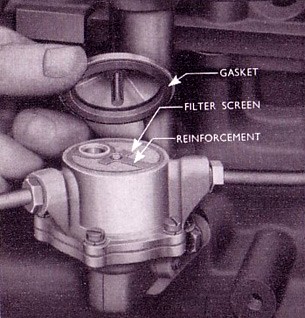

| Clean the Fuel Pump

- (5000 Mile Service) Domed

Cover Type

To service the domed cover type, remove the screw

from the top of the pump and detach the cover and

filter screen. Clean any sediment from the pump

body. Clean the screen in petrol and replace it

on the fuel pump body with the reinforcement

upwards. Check the gaskets to ensure that they

are in good condition and will make an airtight

joint. Renew the gaskets if necessary. Refit the

domed lid and tighten the screw.

|

|

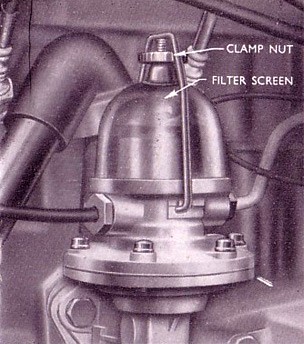

Glass Sediment Bowl Type

To service the glass sediment bowl type pump,

slacken the clamp nut at the top of the pump and

remove he bowl and filter screen. Clean any

sediment from the pump body. Clean the screen in

petrol and replace it on the fuel pump body with

the reinforcement upwards. Check the gasket to

ensure that it is in good condition and will make

an airtight joint. Renew the gasket if necessary.Replace the glass sediment

bowl and tighten the clamp nut

|

|

Checking

Fuel Supply to the Carburettor

If insufficient petrol is reaching the

carburettor, the following points should be

checked:Check that there is sufficient fuel

in the petrol tank.

Check that the filter screen and fuel pump have

not become fouled with sediment.

Check that there is no air leak at any point in

the fuel line connections, which would result in

air being drawn into the system, so that the pump

will not prime.

A comparatively simple test

for fuel delivery can be carried out by

disconnecting the fuel feed pipe to the

carburettor, when a distinct spurt of petrol

should be evident for every two revolutions of

the engine.

Warning –

Petrol is highly flammable. Please ensure you

take suitable precautions if following

Ford’s 50 year old advice.

|

|

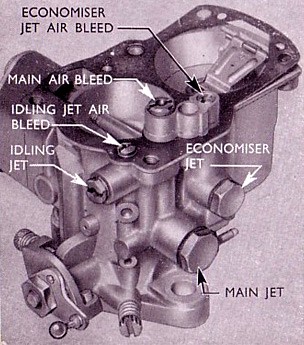

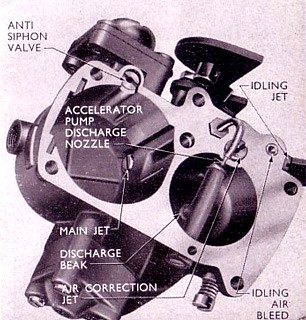

The Carburettor

(fitted prior to May 1962 Type A)

The carburettor is of a downdraft type and

incorporates a special two-stage starting device

on the left hand side of the carburettor body.All adjustments are made at

the time of manufacture and, with the exception

of the idling adjustment, will remain permanently

correct unless disturbed. The idling adjustment

should be checked after the car has been

“run in”.

All petrol jets are

accessible from the outside of the carburettor

and they should be removed and cleaned

periodically. Obstructions should be cleared by

blowing through the jets and passages with a tyre

pump.

On no account use wire or

anything else which could enlarge the jet

orifices, as the jets are calibrated to very fine

limits and not only economy, but general engine

performance can be upset by enlarging the jets in

this manner.

The special

two-stage starting device on the side of the main

body must be used with care, as it is designed to

provide a very rich mixture for cold starting,

when the choke control is pulled right out. Great

care must therefore be taken to follow the

correct starting instructions, otherwise excess

petrol will pass into the engine and may cause

premature engine wear.

|

|

The Carburettor with

Accelerator Pump

(fitted after May 1962 Type B)

The carburettor is of a downdraft type and

incorporates an accelerator pump, an economy

device controlled by manifold depression and a

choke valve of the semi-automatic strangler type

with a friction locking choke control.All adjustments are made at

the time of manufacture and, with the exception

of the idling adjustment, will remain permanently

correct unless disturbed. The idling adjustment

should be checked after the car has been

“run in”.

The air cleaner used with this

carburettor is of the wire gauze type, except on

certain models where a paper element cleaner is

fitted.

Note - On no

account “pump” the accelerator pedal

when starting the engine.

|

|

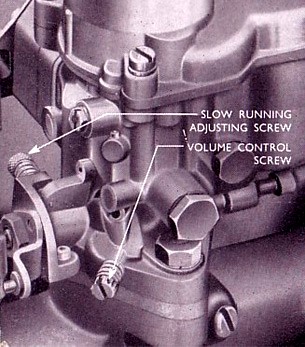

Carburettor Adjustment

- (5000 Mile Service)

The only adjustments required are to the volume

control screw and the slow running adjustment

screw.Idling adjustment must be

carried out when the engine is hot as follow:-

Screw in the slow running adjustment screw until

the idling speed is a little faster than normal.

Unscrew the volume control screw until the engine

begins to “hunt”

Screw the volume control screw in again until the

engine runs evenly. If the engine speed is then

too high, unscrew the slow running screw until a

reasonably slow idling speed is obtained. This

may cause a slight resumption of

“hunting”.

If so screw in the volume control screw until the

idling is perfect.

Note that the volume control screw

alters the volume of mixture passing into the

engine. Screwing it in reduces the volume of

mixture and screwing it out increases the volume.

It may also be necessary to make an

alteration to the distributor timing, in order to

obtain satisfactory idling.

Do not expect a

new engine to idle perfectly at low speeds until

various machined surfaces have had a chance to

“run themselves in”.

|

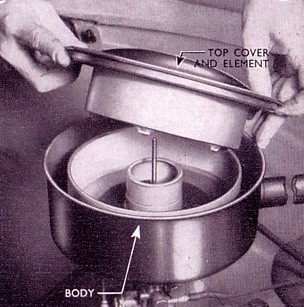

Clean

the Air Cleaner - (5000 Mile Service)

This is fitted

on the top of the carburettor and can be of two

types. This can be either a dry gauze type or an

oil bath type and normally requires servicing

every 5000 miles (8000 km). Should you be

operating your vehicle in a heavily dust-laden

atmosphere, more frequent servicing to the air

cleaner is recommended. The effect of allowing

the internal filter element to become choked with

duct etc, will be to restrict the air supply, in

turn enriching the mixture. Failure to clean this

filter element properly at the correct time can

adversely affect performance and fuel economy. |

Oil Bath Type Air Cleaner

To clean, remove the air cleaner, unscrew the

wing nut on the top cover and lift off the cover

and the cleaner element. Empty the oil and

thoroughly clean the body. Wash the air cleaner

element in petrol to remove the dust and dirt,

and refill the air cleaner body with fresh engine

oil up to the level of the arrow stamped on the

side. Check that the cork gaskets are in good

condition, refit the element and the cover. Refit

the air cleaner to the carburettor. |

|

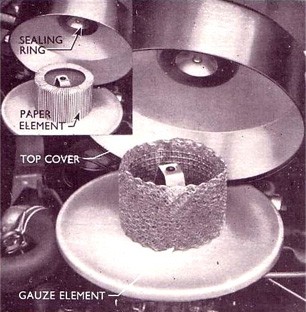

Dry Gauze Type Air Cleaner

To clean, remove the air cleaner by slackening

the clamp securing it to the carburettor. Pour a

small amount of petrol into the cleaner via a

larger diameter aperture (where the carburettor

connection hose is fitted), swill round and pour

out of the “spout”. This procedure

should always be adopted, otherwise the tendency

will be to wash the dirt in the cleaner further

into the gauze. The element should be lightly

oiled, adopting the same procedure, any surplus

oil being allowed to drain off. Refit the air

cleaner to the carburettor. |

|

Paper

Element Type Air Cleaner

This is very similar to the wet type of air

cleaner, but instead of having a gauze element it

has a special paper one. This paper element must

not be washed or oiled. Stand the element

vertically and tap it on a firm flat surface

while slowly rotating it. Check the element for

tears in the paper or signs that it is so clogged

that the tapping treatment will not clear it.

Renew the element if it is defective. |

Information taken from Various Ford

Anglia Instruction Books and Handbooks..

Warning -

The Health and Safety bit.

Please note your health may be at

risk if you do not take sensible safety

precautions. Never work under an unsupported

vehicle, do not take shortcuts. If you feel that

the task is beyond your capabilities, then employ

the services of a trained professional. The Owner

of this Website nor the author cannot be held

responsible for any accidents or injury arising

from advice given on this webpage. Safety advice

can be obtained from the RoSPA.

|

|

|